By Lex A. Parker/photos by the author

By Lex A. Parker/photos by the author

I have made several visits to Silverton, Colo., as part of my interest in the Rio Grande narrow gauge railroad. I model it as it existed in Chama, N.M., in the mid-1930s. Silverton can be visited by road, but one mustn’t miss the opportunity to take the Durango & Silverton train for an outstanding ride from Durango and return through canyons that follow above the Animas River along exhilarating cliff edges, before dropping to water level and into Silverton.

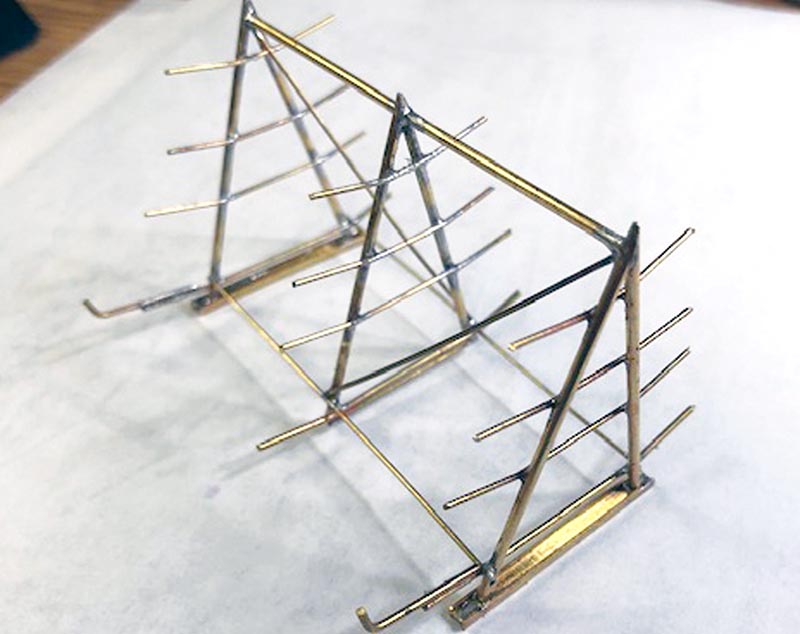

It was on one of these trips, as I wandered around the small yards, that I came across this interesting and simple piece of equipment. While I did not have measuring equipment with me, the measurements did not have to be exact, and my photographs were enough to “guesstimate” sizes. Recently, I decided I needed a small project to add to my layout and prepared a simple line drawing to build on as a template. I’ve estimated the sizes that would make sense given the structural ap-pearance and use. Pipe and bar stock, even short lengths of rail or old timbers, could be stored on this rack. As you can see, based on size and weight needed to lift it up, large diameter pipe would be stored on the lower racks. My model is in 1/48 scale; other scale components would be adjusted accordingly.

I used what I could see in the photo to approximate the size of the rack with a height that would make sense when lifting steel up on the racks. I made a simple drawing of the layout to use as a template. As I usually do when duplicating items, I glue scrap wood on either side of the components to hold them in place as they are either soldered or glued. The short vertical lines on the ends were a guide to bend the wire upward. This was done so the pipes would not roll off the rack.

I used 5” diameter brass wire rod to form the legs, beveled the top, and then soldered to meet at a point. A temporary brass wire was soldered across the bottom to hold the shape. I filed the top joint to clean up any solder for a nice finish. Next, 2” diameter brass wire was cut to length and soldered across the leg frames. The prototype ran the rods through the legs, but this was not easily done at this scale…